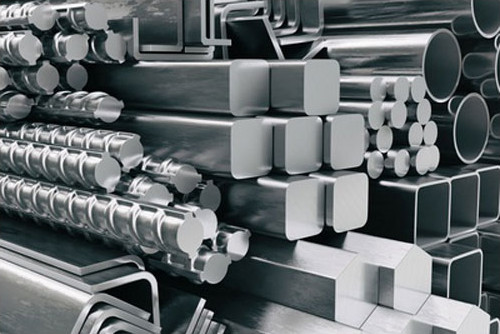

METALLURGICAL ROLLS, DIE BLOCKS, FORGED PRODUCTS

One of the main domains of the operations of the Rolls-Rolls, Inc. Company is the production and delivery of tools for plastic working, mainly rolls and drop forging dies for hammers and presses, to steelworks and metallurgical processing plants (forges, mills). These are tools of a high crack resistance, abrasion resistance and thermal tempering resistance.

MORE

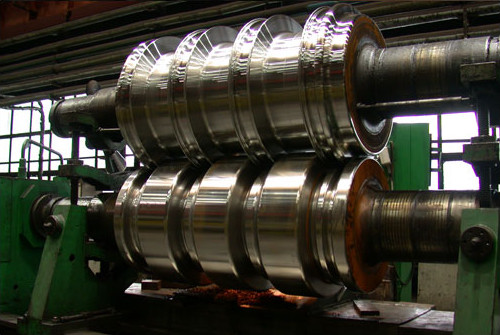

They are made of steels, which chemical compositions and heat treatment technologies are strongly guarded secrets of the Company. Precisely collected data bases concerning the influence of individual alloy elements, combined with long term experience, allow producing of tools of unusual, and sometimes even of unimaginably excellent, properties.

These can be flat and grooved rolls, for cold and hot works, die blocks for presses and hammers as well as different tools and forged products from which a high crack, abrasion and thermal tempering resistance - at maintaining their high hardness - is required.

Our products: metallurgical rolls, drop forging dies and other forgings are successfully operating in several steelworks, forges and other manufacturing plants. Working and backing-up rolls for sheet rolling and mandrels for pilgrim rolling of tubes are used in Batory Steelworks. Mandrels for pilgrim rolling of tubes are used in Częstochowa Steelworks. Shape rolls are operating in Zawiercie Steelworks. ArcelorMittal Poland uses shape and flat rolls (for universal stands). We made main shafts (28 tonnes) for wind power plants in

Ostrowiec Steelworks, and flat rolls in Cold Mill of Termetal Company in Piła, in forges: Tasta Armatura in Stalowa Wola and Aesculap Chifa in Nowy Tomyśl we made drop forging dies.

LESS